Specialties Include:

- High Altitude Electromagnetic Pulse (HEMP) Shielded Enclosures

- Meets or exceeds MIL-STD-188-125

- Low Risk fabrication per MIL-HDBK-423 for Time Sensitive facilities

- Specialized enclosure to mitigate the effects of geomagnetic storms

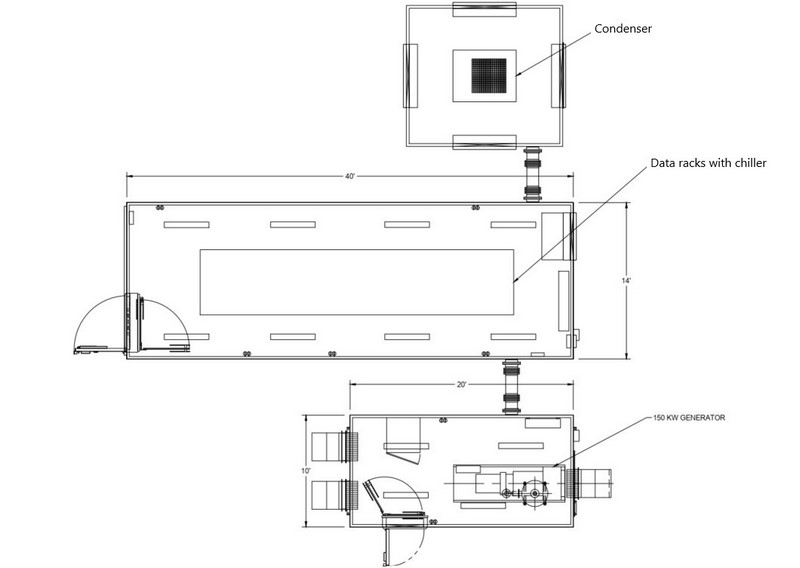

- HEMP protected data centers

- Customized HEMP shielding enclosures for existing electrical generators

- Custom HEMP protected rooms designed to any size or application

- Generator Controls & SCADA systems

- Circuit Breaker and Switchgear Rebuild

- Power System Studies

- Repair and Maintenance

- Single- and multi-unit integrated facilities with modular “building block” attachment methods.

- Custom designs available up to 5,000 sq. ft.

- HVAC Climate Control

- Equipment Racks & UPS

- Intrusion Detection System

- Fire Suppression System

Custom Products and Services

- Generator Paralleling Controls

- Ground Bus Bars

- Uninterruptible Power Systems (UPS’s)

- Automated HEMP Disconnect Switch

HEMP Protected Generator Shelters

- The EMP Engineering Team has designed, fabricated, and integrated several HEMP protected communications shelters and UPS systems for the U.S. Missile Defense Agency

– Ballistic Missile Defense System (BMDS) Communications and Support Complex – Transportable (BCSC-T)

– Thule Communications and Control HEMP Room (C2HR)

– Thule C2HR HEMP Power System (HPS)

– Ft. Greely, Alaska HPS

- In-House HEMP Shielding Capabilities

31,000 ft² building

Sheet Metal Working

– Computer Numerical Control (CNC) Plasma Cutter

– 12ft CNC Sheet Metal Brake

– 12ft Sheet Metal Shear

Welding

– Shielded Metal Arc Welding (SMAW)

– Metal Inert Gas (MIG) Welding

– Tungsten Inert Gas (TIG) Welding

- All shield welds are tested prior to shipment

SELDS testing

Magnet particle inspection

Die penetrate testing

HEMP Shield Effectiveness QA testing

– MIL-STD-188-125-1

– MIL-STD-188-125-2

- DoD command and control center HEMP Shielding